Hydraulic Power Units from Magister Hydraulics

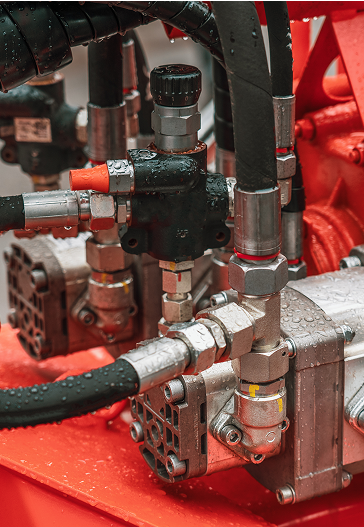

Hydraulic Control Valves

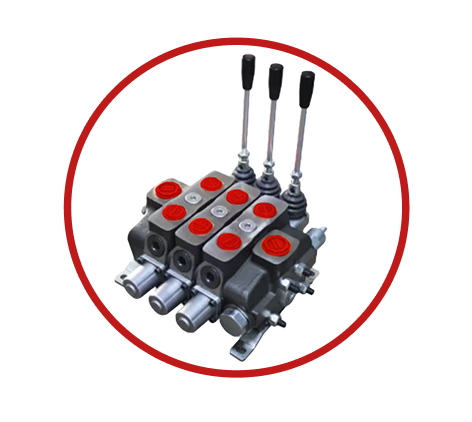

Manual Control Valves

Manual Control Valves

Monoblock Control Valves

Monoblock Control Valves

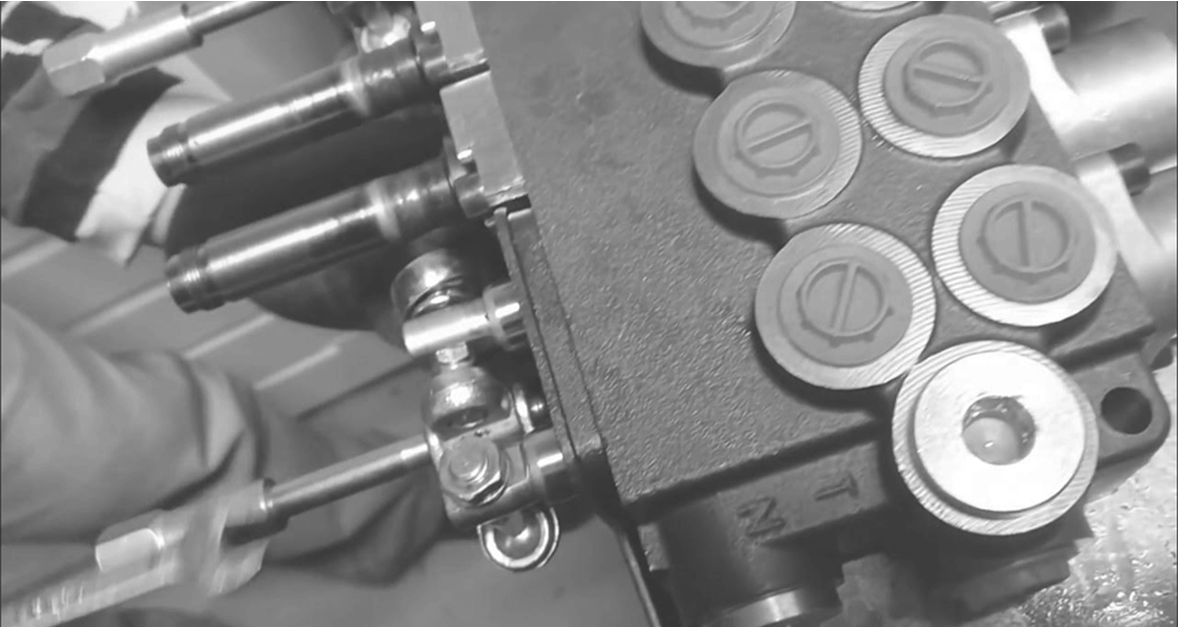

Sectional Control Valves

Sectional Control Valves

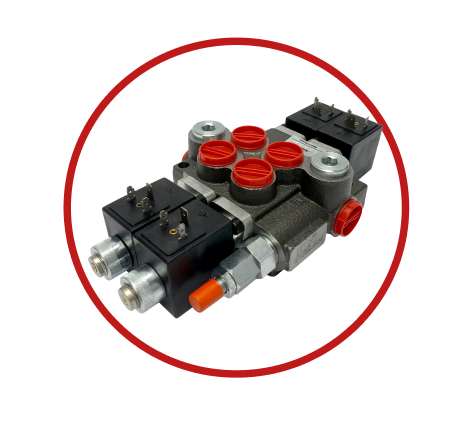

Solenoid Control Valves

Solenoid Control Valves

Hydraulic Diverter Valves

Hydraulic Diverter Valves

Flow Control Valves

Flow Control Valves

Hydraulic Check Valves

Hydraulic Check Valves

Pressure Relief Valves

Pressure Relief Valves

Hydraulic Manifolds

Hydraulic Manifolds

Custom Hydraulic Control Valves

- Directional Control Valves:These valves control the direction of the hydraulic flow, essential for guiding fluid within the system. They are available in various configurations, including 2-way, 3-way, and 4-way versions, depending on the number of flow paths required.

- Solenoid Operated Valves:These electrically controlled valves provide remote operation capabilities with custom solenoid options for different voltage requirements, response times, and environmental conditions.

- Manual: Hand-operated valves for applications where manual control is preferred or required.

- Electric (Solenoid): Valves are operated by electric solenoids for remote or automated control, ideal for complex or multi-function systems.

- Hydraulic: Pilot-operated valves for precise control in high-pressure environments.

- Subplate Mounted: Designed for easy installation and replacement on standard subplates.

- Cartridge Style: Compact valves are inserted into manifold blocks, perfect for integrating into complex hydraulic circuits.

- Inline Mounted: Standalone valves are mounted directly in the flow line, offering straightforward installation.

- Modular Stacking: Allows multiple valves to be stacked together, creating compact and versatile hydraulic systems.

- Body Materials: Options include cast iron, aluminum, stainless steel, and special alloys for specific environments (e.g., high pressure, corrosive).

- Seal Types: Custom seals, such as Viton, NBR (Nitrile), EPDM, or PTFE, based on fluid type, temperature range, and pressure requirements.

- Custom Port Sizes: From standard NPT, SAE, and BSPP to custom specifications to match your system requirements.

- Threaded or Flanged Ports: Options to suit various piping connections and system designs.

- Customized Pressure Ranges: Valves can be configured to handle low to extremely high pressures if needed.

- Variable Flow Capacities: Tailored flow rates from minimal to several hundred gallons per minute (GPM), ensuring optimal performance for your specific application.

- Pressure Compensation: Ensures consistent flow regardless of load changes.

- Adjustable Settings: Allows for on-site fine-tuning of pressure, flow, or response time.

Industries We Serve

Material Handling and Logistics:

Material Handling and Logistics:

Applications: Forklifts, pallet jacks, scissor lifts, and dock levelers.

Construction:

Construction:

Applications: Excavators, loaders, cranes, pile drivers, concrete pumps, and drilling rigs.

Agriculture

Agriculture

Applications: Tractors, harvesters, irrigation systems, and balers.

Utility Services:

Utility Services:

Applications: Garbage trucks, snow plows, and utility maintenance vehicles.

Automotive Industry:

Automotive Industry:

Applications: Vehicle lifts, assembly line equipment, and hydraulic testing systems.

Marine Industry:

Marine Industry:

Applications: Ship steering systems, winches, deck cranes, and stabilizers.

Mining Industry:

Mining Industry:

Applications: Drilling rigs, conveyor belts, rock crushers, and underground vehicles.

Manufacturing:

Manufacturing:

Applications: Presses, injection molding machines, conveyors, and metal forming equipment.

Contact us

Magister Hydraulics is committed to delivering hydraulic solutions that drive success. Let us help you elevate your equipment’s performance with custom-designed hydraulic power units tailored specifically to your needs. Contact us today to discuss your project.