MagisterHydraulics

2022We created the help guide below to provide immediate assistance in the hydraulic industry. This information was created based on thousands of inquiries and questions received by Magister Hydraulics’ clients. We collected the data and put together the help guide for your reference. See below the most frequently asked questions, tutorials and knowledgeable articles.

How to Add a Hydraulic Valve to a Tractor

There are many agricultural tools and machines that employ hydraulics for smooth working. And note that a tractor is among these powerful and sturdy machines that rely or depend on the sheer power...

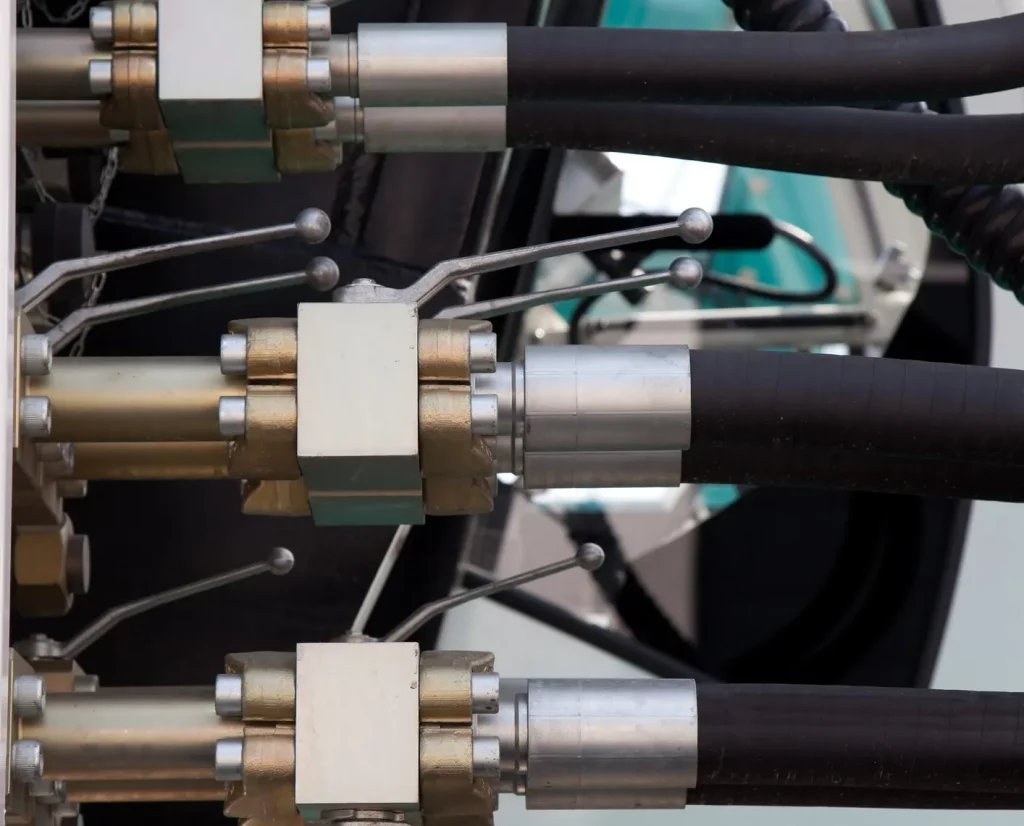

How to Replace a Hydraulic Hose

Hydraulic hoses and various couplings are the crucial components of most construction machines and agricultural parts and equipment. You know that couplings and hoses are integral to all hydraulic...

MagisterHydraulics

2022

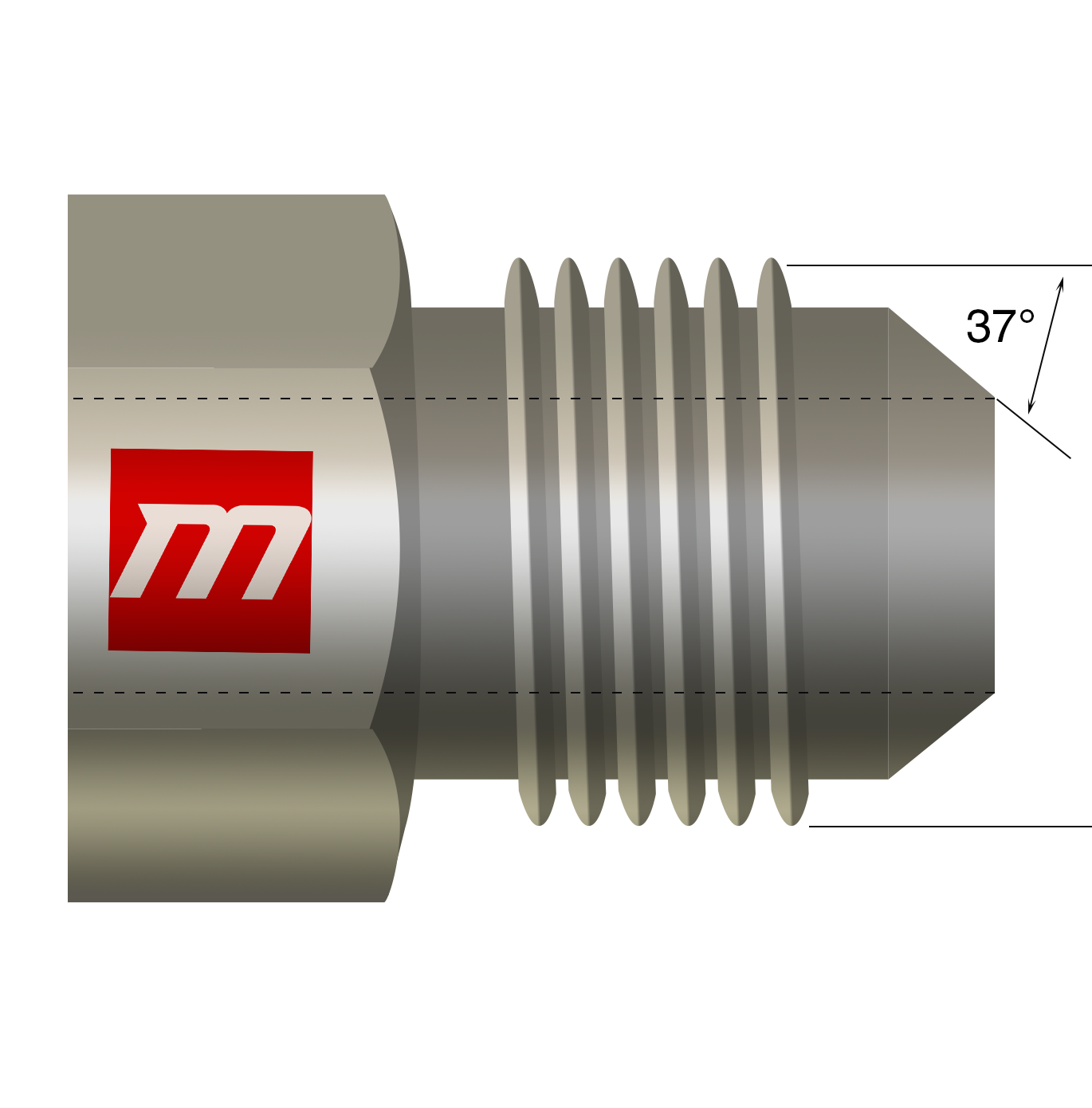

Hydraulic ports tutorial

Synopsis Acronyms Brief Introduction Recognition tools Connections from the U.S. National Pipe Tapered Fuel National Pipe straight mechanical JIC 37° Flare SAE 45°...

MagisterHydraulics

2021

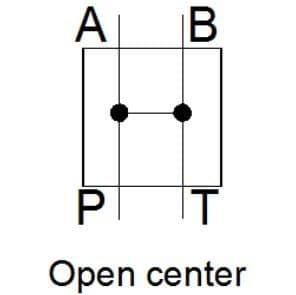

Directional Control Valve Center Options

Directional Control Valve Centers Directional control valves are an important component in hydraulic systems, allowing operators to control the flow of fluid and the direction of movement in...

MagisterHydraulics

2021

What has to be taken into consideration in the choice and use of hydraulic hoses?

Hydraulic high-pressure hoses, with four-fold security to prevent bursts, should be used as connector hoses. In addition to the four preferred lengths, lengths are also supplied up to customer...

MagisterHydraulics

2021

Hydraulic System Maintenance

Maintenance of Hydraulic System Maintaining a hydraulic system is important for its efficient and reliable operation. Here are some steps for effective hydraulic system...

MagisterHydraulics

2021

Hydraulic system troubleshooting

Hydraulic systems help machines work, but sometimes they can have problems. This guide is here to help you fix those issues. We’ll talk about things like leaks, pressure troubles, and how to...

MagisterHydraulics

2021

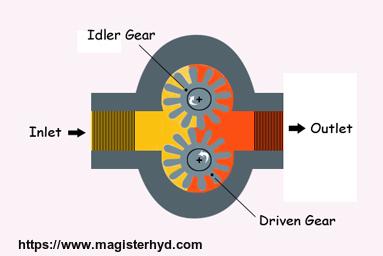

What hydraulic pump do I need for my application?

Selecting the Right Hydraulic Gear Pump for Your Needs Hydraulic gear pumps are a workhorse in the world of fluid power. They’re known for their reliability, simplicity, and ability to handle...

MagisterHydraulics

2021

What are the common causes of hydraulic cylinder failure?

Side loading Side loading is a very common hydraulic cylinder failure, which is caused from the cylinder being misaligned which creates an unparalleled force on the piston rod. Hydraulic...

MagisterHydraulics

2021

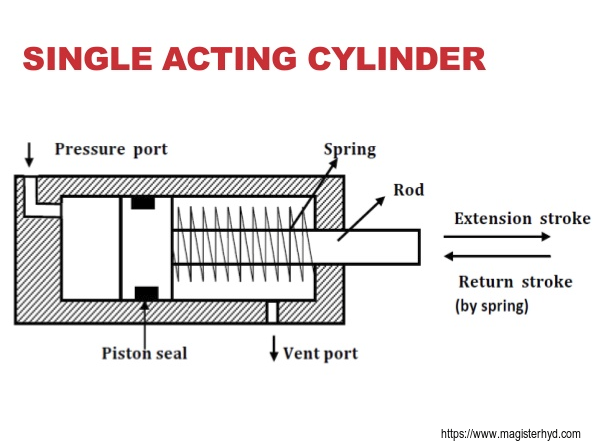

What is the difference between double and single acting hydraulic cylinders?

Single vs. Double Acting Hydraulic Cylinders In the heart of hydraulics lies the mighty cylinder, a piston-driven powerhouse that converts fluid pressure into linear motion. But within this...

MagisterHydraulics

2021

How to choose and use hydraulic cylinders safely?

Many of the failures in a hydraulic system show similar symptoms: a gradual or sudden loss of high pressure, resulting in the loss of power or speed in the cylinders. In fact, the cylinder may stall...

MagisterHydraulics

2021

How Many Types of Hydraulic Cylinders Are There?

The three most common hydraulic cylinder configurations are piston hydraulic cylinders, telescopic hydraulic cylinders, and plunger hydraulic cylinders. Each cylinder design varies by the type of...

MagisterHydraulics

2021

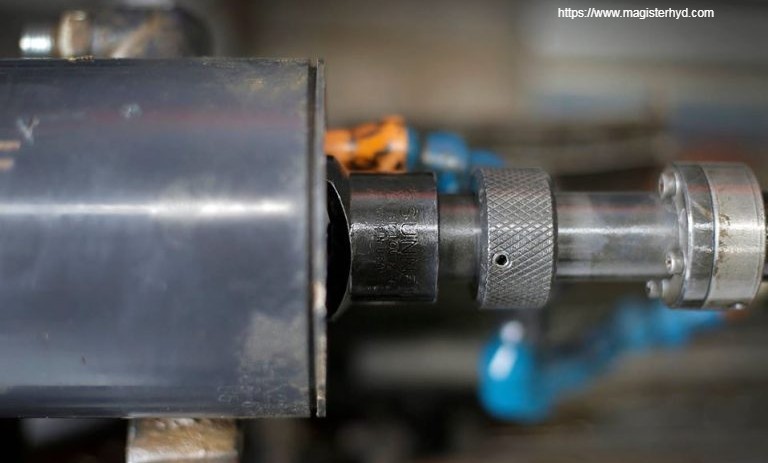

How to repair hydraulic cylinders?

Hydraulic cylinders take a significant part of the entire hydraulic system. They are mechanical actuators that provide the unidirectional force. Integration of hydraulic cylinders will eliminate...

MagisterHydraulics

2021

How to change hydraulic cylinders?

In most times, a hydraulic cylinder can be repaired by changing out pistons or seals inside the cylinder. However, on rare occasions, you may need to replace the entire cylinder itself. If that...

MagisterHydraulics

2021

Dieseling in Hydraulic Cylinders

Hydraulic Cylinder Dieseling Hydraulic dieseling, often referred to as the dieseling effect, happens when air gets mixed with hydraulic cylinder oil, resulting in the formation of bubbles within the...

MagisterHydraulics

2020

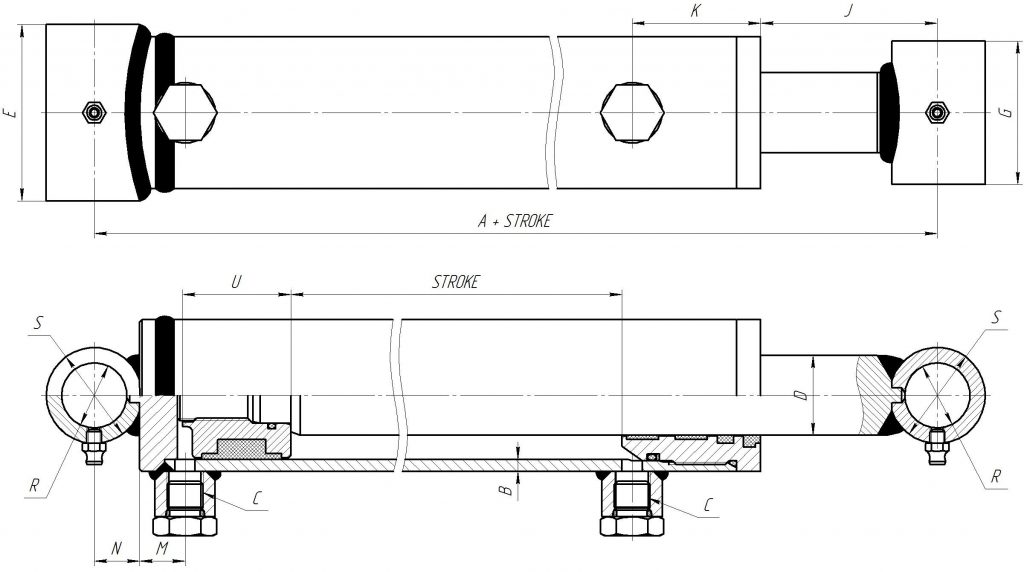

How to measure a hydraulic cylinder replacement?

In order to measure and decide which hydraulic cylinder you need, first of all you would have to visually determine the type of hydraulic cylinder you try to replace. Here are the the main three...

MagisterHydraulics

2020

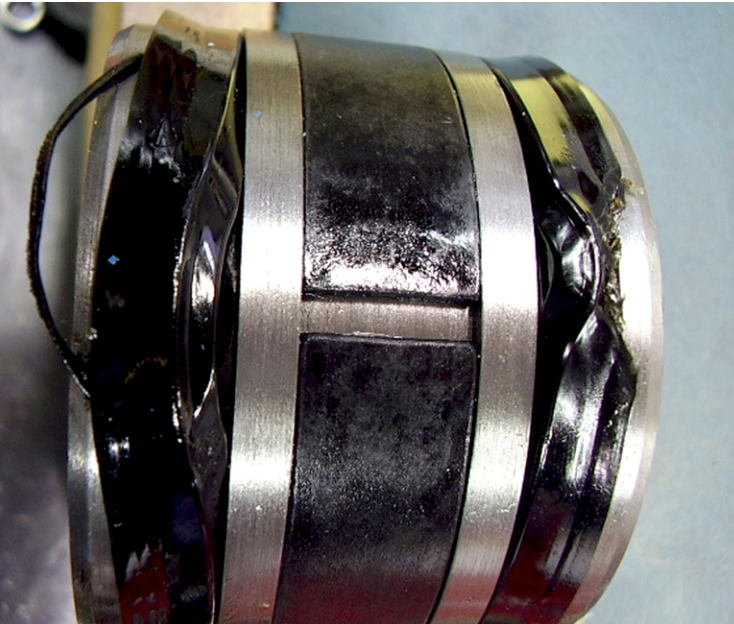

Why do hydraulic cylinders start leaking?

Why do hydraulic cylinders start leaking? Seals play a major role in hydraulic cylinders – they contain the fluid and prevent the leakage of fluid. The seals for a rod sealing system...

MagisterHydraulics

2020

How to choose hydraulic oil?

It’s more than common to deal with lubricated machines and most of us love to take good care of them. Just like we love to maintain our health and fitness by taking healthy food and...

MagisterHydraulics

2020

Basics of Hydraulic Directional Control Valves

About Direction Control Valve and Classification The hydraulic directional control valves can start, stop, and control the direction of the flow. They are classified according to principal...

MagisterHydraulics

2020

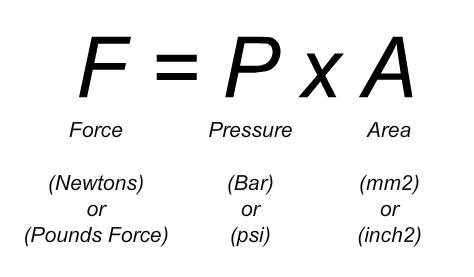

Fluid Power Formulas

Fluid power formulas refer to a collection of mathematical equations and calculations that are used to analyze and understand the behavior of fluids, particularly in hydraulic and pneumatic...

MagisterHydraulics

2020

Hydraulic hoses explained

A hydraulic hose is used to send hydraulic oil to hydraulic components, valves, actuators, and other hydraulic tools. Any type of hydraulic hoses are required to meet stringent standards to accustom...

MagisterHydraulics

2020

Basics of Hydraulic Hose Fittings

How to determine proper hydraulic hose fittings? Nowadays there are numerous types of tools and machinery that require a specific kind of sealing. Thread types also vary according to design...

MagisterHydraulics

2020

Basics of Hydraulic Gear Pumps

A comprehensive guide on Gear Pump Define the gear pump. The gear pump is a PD (Positive displacement) pump. It helps to develop a flow by carrying the fluid between repeatedly enclosing interlocking...

MagisterHydraulics

2020

Drift in Hydraulic Cylinder

Drift Causes of Hydraulic Cylinder Indeed, the hydraulic system can have its challenges. When the hydraulic system has quit working, the primary thing that you should do is to check its hoses get...

MagisterHydraulics

2020